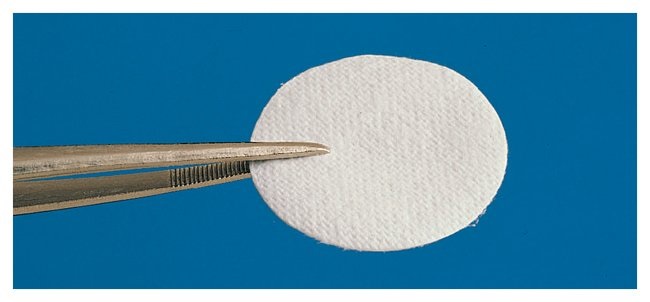

Glass microfiber filters combine fast flow rates with high loading capability and the retention of very minute particles that extends up to the sub-micron level. Glass microfiber filters can be safely used at temperatures up to 500 degree Celcius and are perfect for use indifferent applications that involve air filtration and for gravimetrice valuation of unstable materials where ignition is involved.

Glass microfiber filters have a delicate capillary structure and can soak upconsiderably larger quantities of water compared to a conventional cellulose filter. This makes it suitable for liquid scintillation counting methods and spot tests. The microfiber filters can also be made totally translucent and see through for succeeding microscopic examination. The particle loading capability of any filtration system can be significantly increased by utilizing a prefilter. Glass microfiber filters such as Whatman GF/B or GF/D are suggested because of its high particle loading capacity and low resistance to fluid flow. What man Multigrade GMF 150 is especially important for the prefiltration of more significant volumes and solutions that are usually difficult to filter.

Glass microfiber filters provides high flow rate and fine particle retention with excellent loading capacity. These types of filters are often used for high-efficiency multipurpose laboratory filtration that range from filtration of water to water pollution monitoring of wastes, algae and bacteria cultures, protein filtration, food analysis, and radio immunoassay of weak beta emitters. Depending on the brand and specific design, glass micro fiber filters are recommended for gravimetric examination and analysis of airborne particulates, stack sampling as well as absorption methods of air pollution monitoring.

This high-efficiency glass microfiber filters will hold minute particles down to 0.7 µm. Compared to membrane filters with a similar retention value, this type of filter has a very fast flow rate and atremendously high loading capacity. Because of the close fitting specification of 0.6 µm – 0.8 µm particle retention and unadulterated borosilicate glass structure, GF/F is the material upon which the EPA Method TCLP 1311 for Toxicity Characteristic Leaching Procedure was developed. This remains as today’s filter of choice across all industry.

The innovation in filtration methods and the introduction of glass microfiber filters enable laboratories to perform their tests in a more accurate manner with precision results at all times. This technological marvel in research and development plays a major role for the success of all tests and filtration ventures be it in a laboratory or on the field.