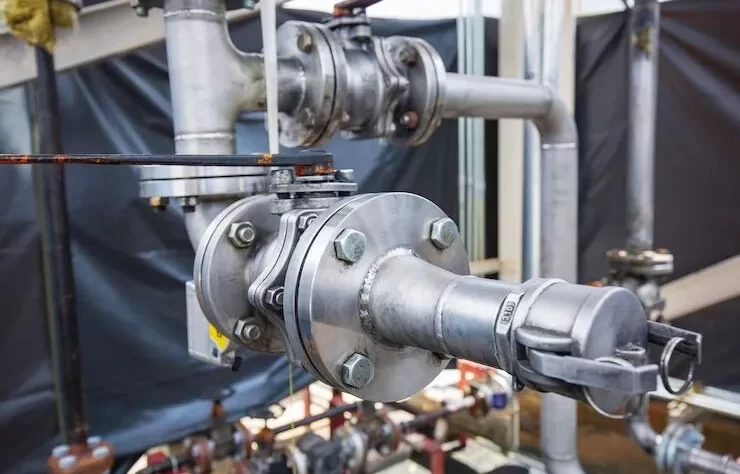

Control valves have always been the unheralded task force of industrial processes, softly regulating fluids and gases to maintain operational efficiency. These changes are, however, taking place at an unprecedented rate because of the advancement in technology where all elements of innovation and functions have to be incorporated into control valves. Today’s control valves, such as Siemens rdy2000bn, are getting smarter, more flexible, and environmentally better.

- Intelligent Automation: The next phase for control valves is clearly smart. Leveraging sensors and data analytics, these valves are becoming an increasingly important part of industrial automation and enabling real-time adjustments to optimize system performance. Intelligent control valves improve efficiency and reduce energy use and operation costs.

- Predictive Maintenance: This is, however, a thing of the past, since it involves reactive maintenance. Modern-day Control valves incorporate predictive maintenance, which includes the use of insights derived from data and prediction algorithms to forecast possible problems and schedule proactive maintenance. This transition reduces downtime and enhances dependability and maintenance expenditure.

- Versatility and Adaptability: Nowadays, a one-size-fits-all solution is not feasible for control valves. This ensures they are highly modular for tailoring to specific applications and Spanning. This flexibility makes control valves capable of meeting various process needs and conditions.

- Smart Diagnostics: Control valves in the advanced class support valve performance monitoring systems. Once slightly odd, these smart diagnostics give early warnings and adjustment recommendations that prevent high costs of breakdowns but still ensure undisrupted operations.

- Energy Efficiency: Control Valves Key to Energy Efficiency. These are intended to ensure the use of the least energy, create lower emissions, and proper use of resources that are in line with sustainable global living.

- Remote Connectivity: The future control valves are very connected which permits remote monitoring and control. This enables operators to adjust valve settings remotely, which boosts operational flexibility, improves safety, and reduces the requirement for on-site personnel.

- Cybersecurity Measures: Robust cybersecurity is deployed to protect against cyber threats and guarantee the trustworthiness of industrial processes as control valves are made more networked.

The control valves represent a confluence of innovation and functionality for automation in the industrial sector. More than simply flow regulators, these advanced control valves are building blocks in the development of smarter and sustainable± industrial processes. However, it is not prudent for industries that desire to develop with the ever-changing world, to take advantage of these developments. Total Control Valve Line for Seamless Integration and Service Flexibility in Industrial Systems Now Comes with Smart Controls.

Visit website to get more info.